Just one correction iteration before mass production

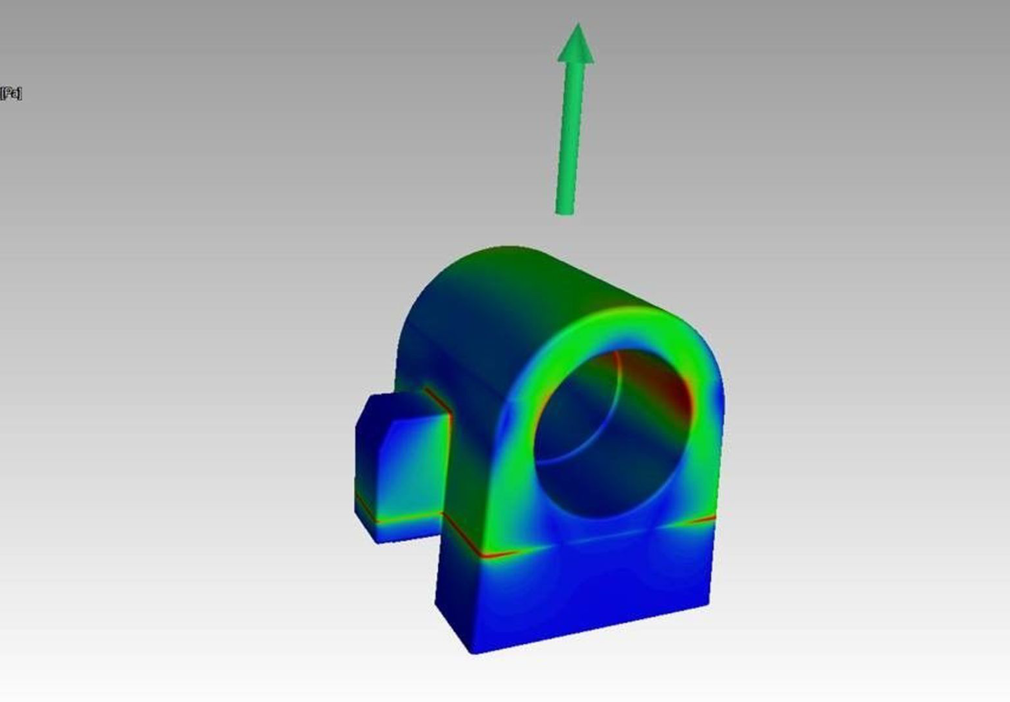

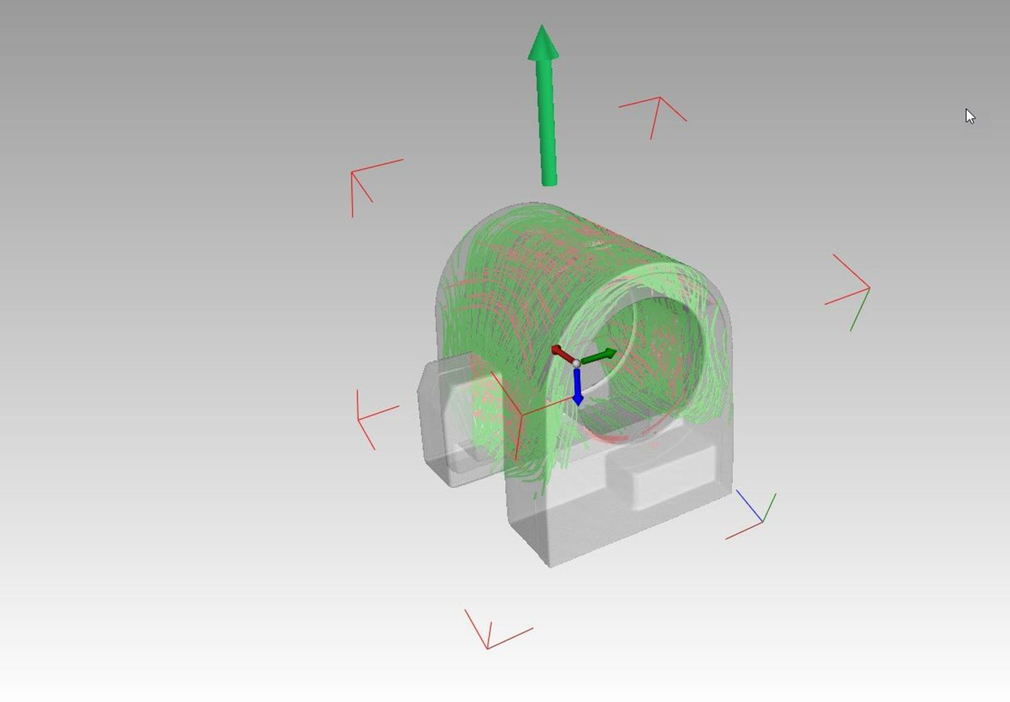

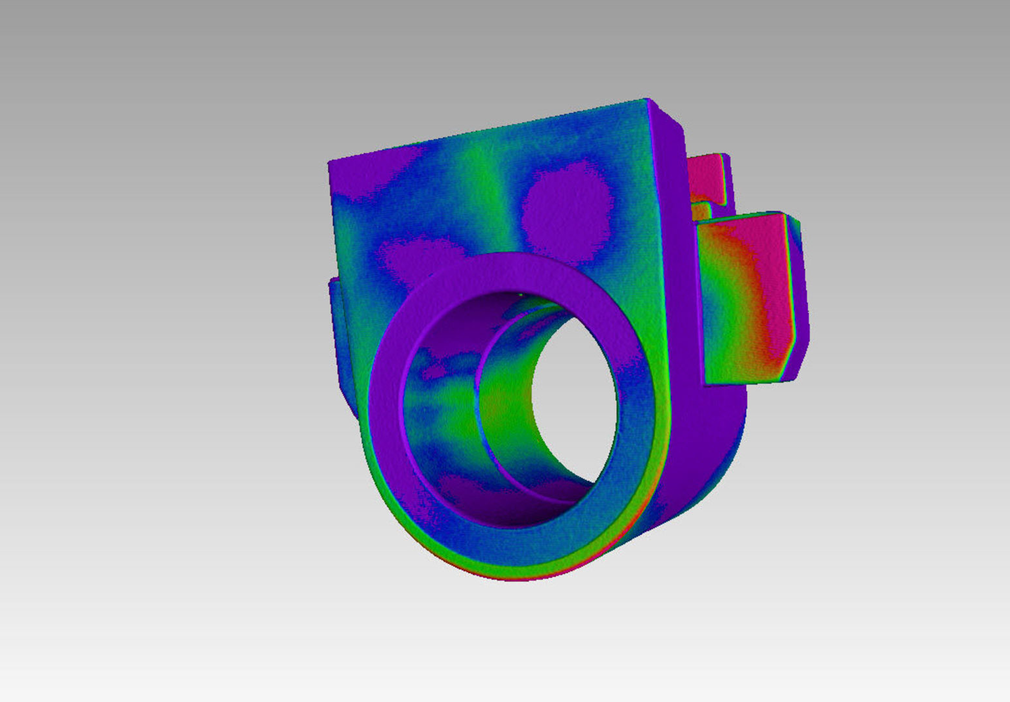

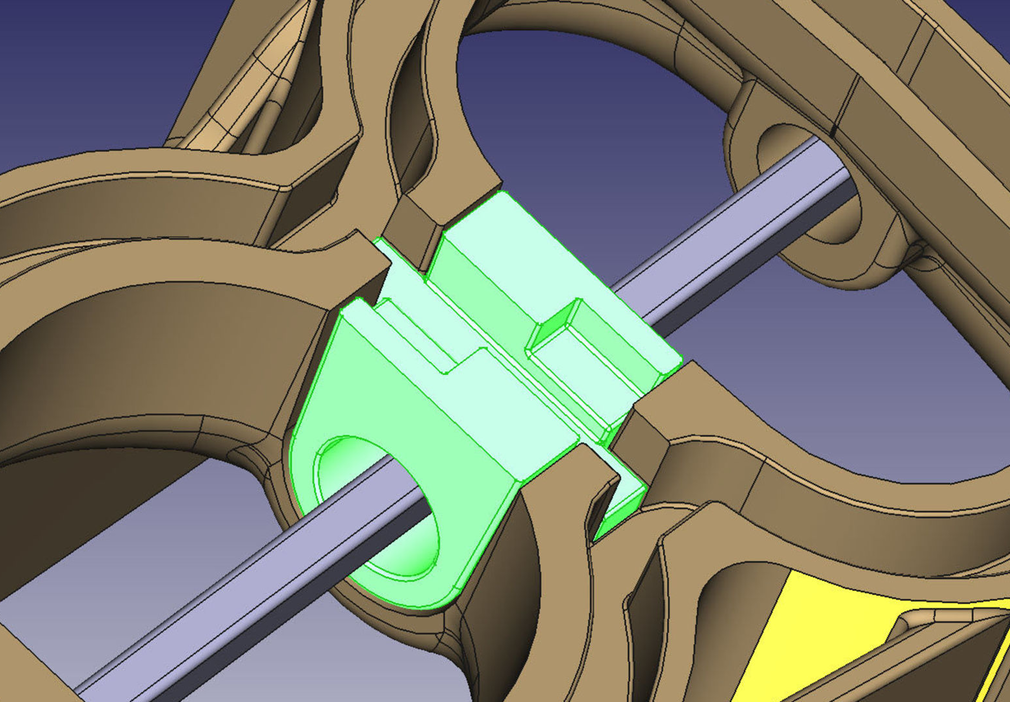

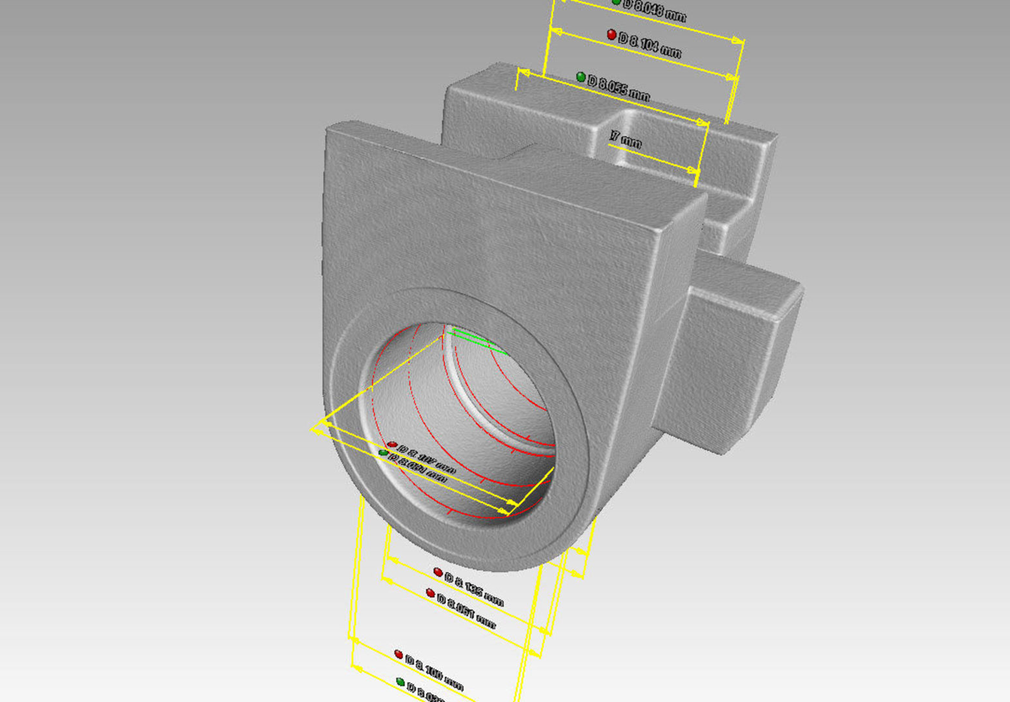

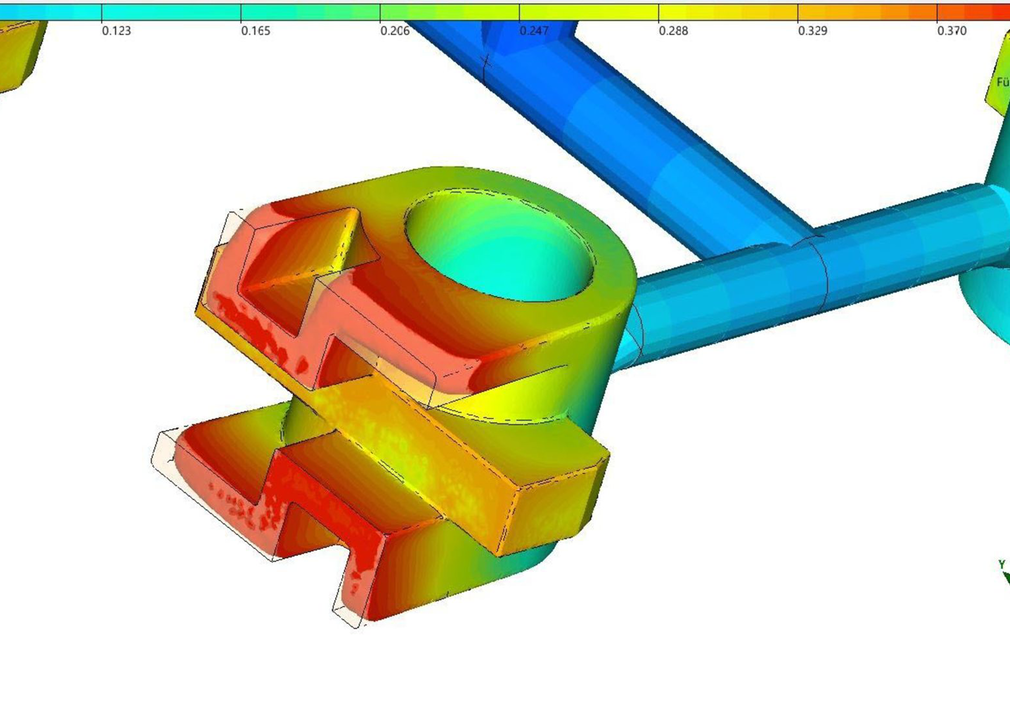

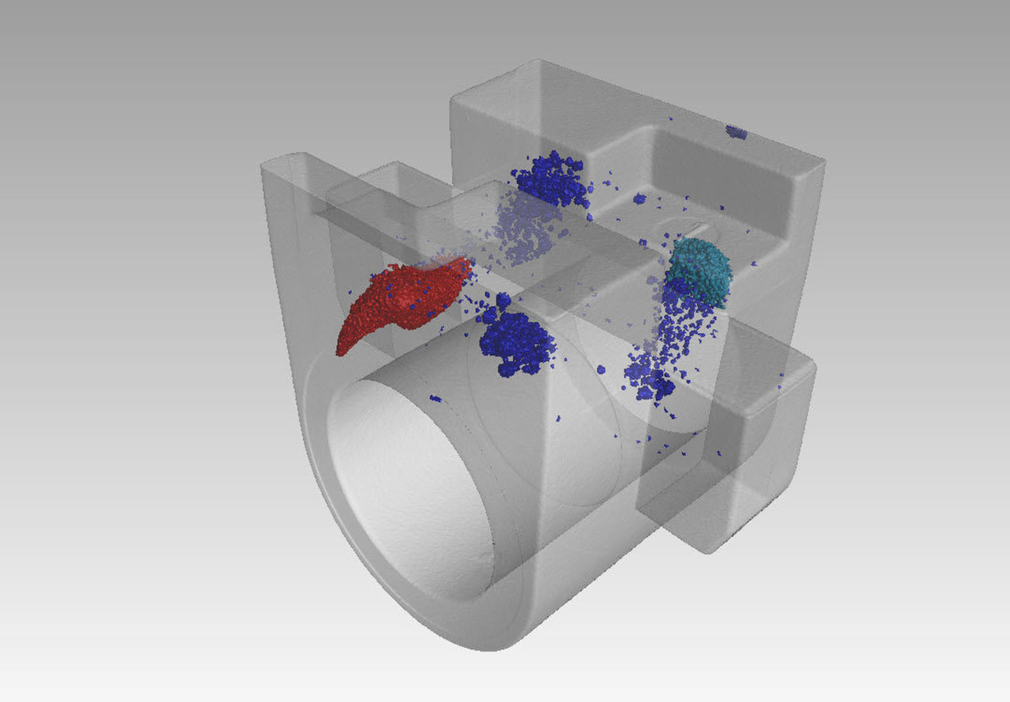

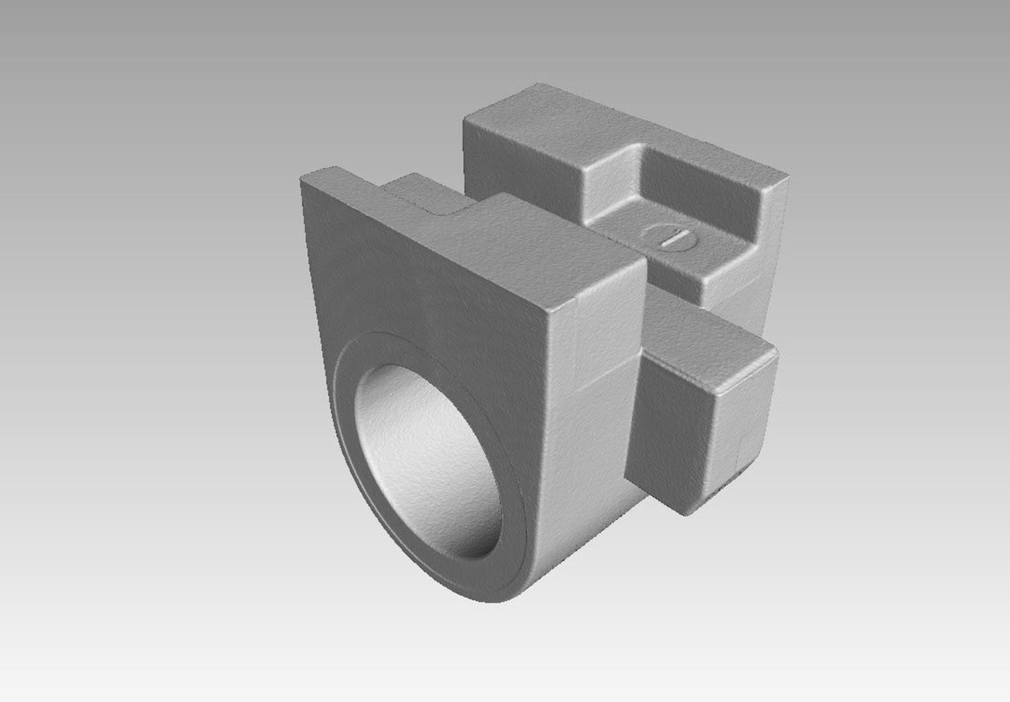

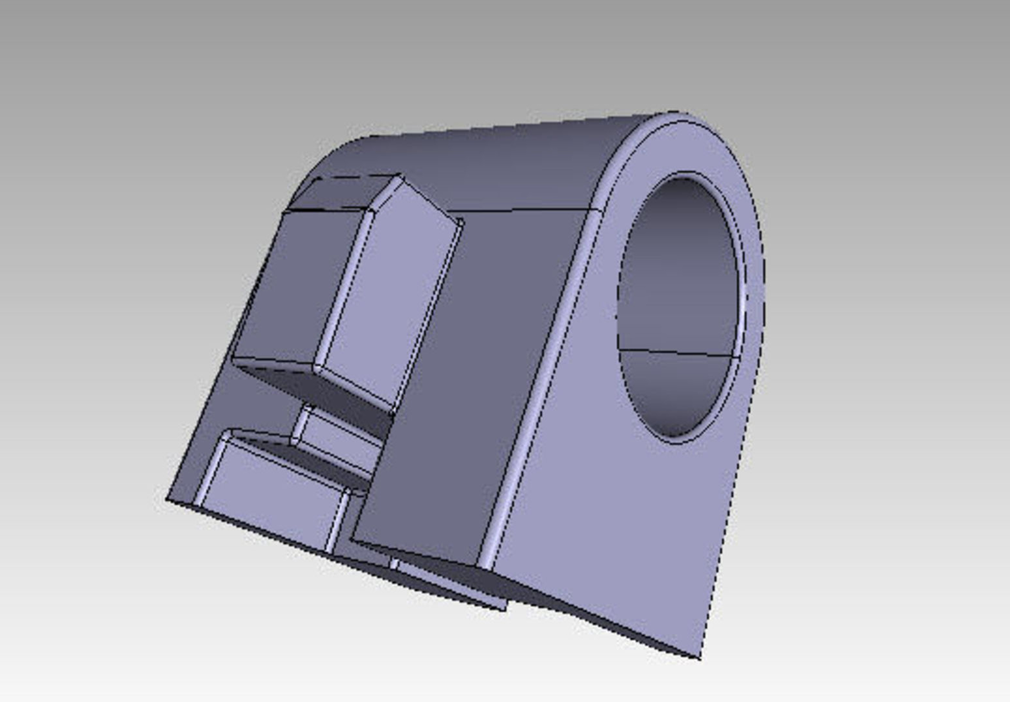

Issues arose with a plastic bearing’s ability to handle prolonged loads once it was integrated into the system. Using computed tomography, we digitized the component and captured its entire internal material structure. Based on the CT data, we were able to perform a nominal-actual comparison, a 3D measurement, and a defect analysis. The measurements showed that the bearing bore holes were slightly elliptical. Furthermore, there were significant vacuoles (small cavities) within some areas of the material. In a virtual load test, performed directly on the CT data, the parts exhibited the same defects as in the real-world situation. Based on these findings, our customer made corrections to the injection molding parameters. This eliminated the need for a tool correction loop, which resulted in further cost savings. We tested the improved component in a simulation, and the customer was then able to finalize the optimization of the plastic bearing before commencing series production.