Computed tomography

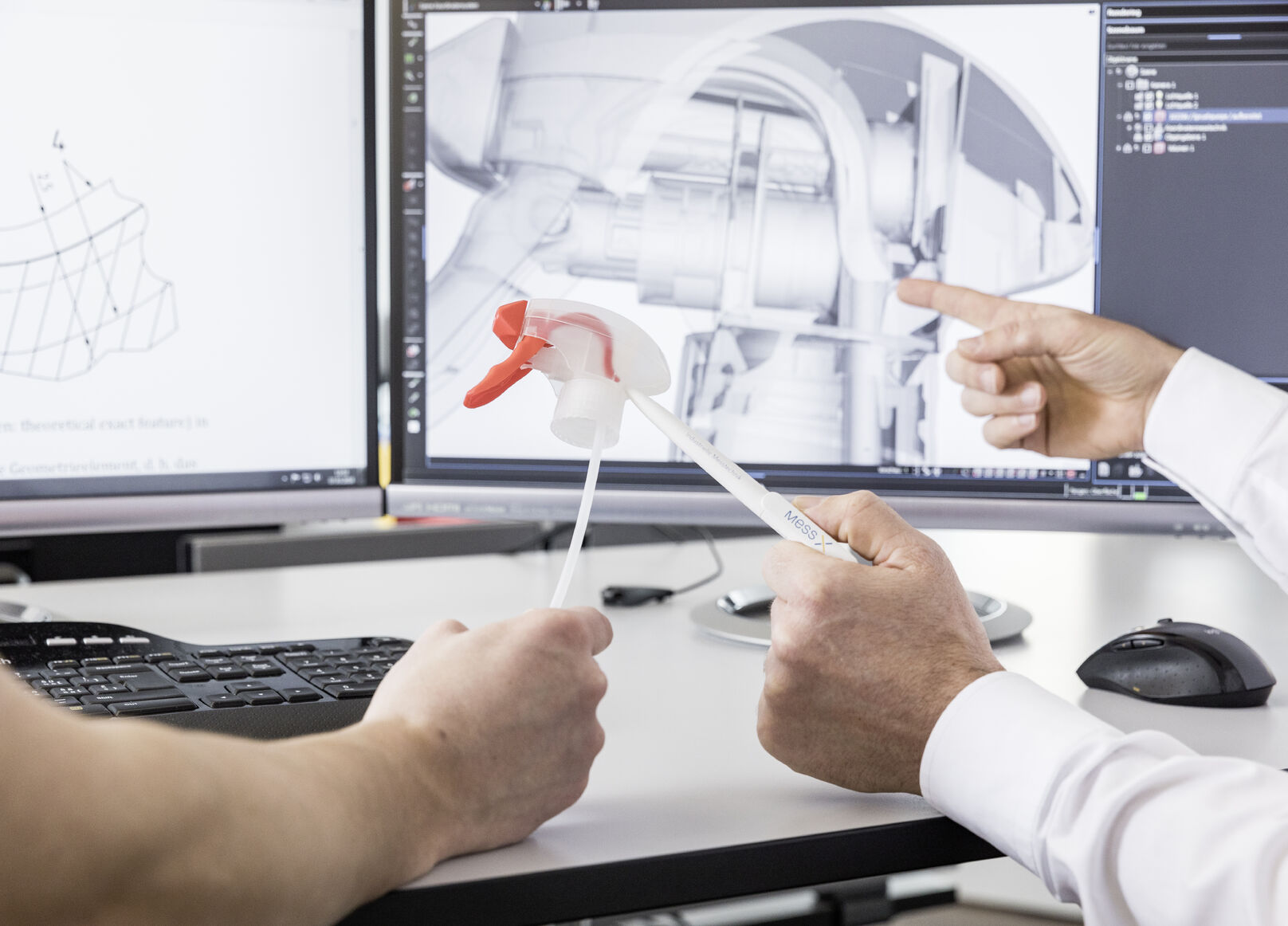

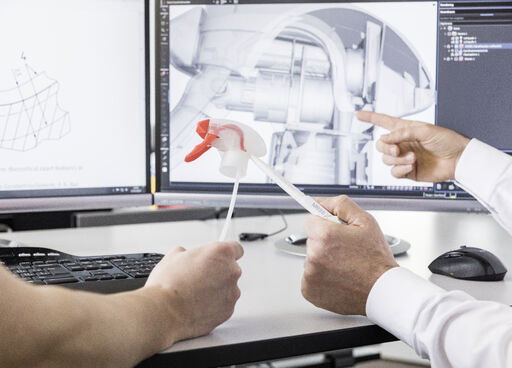

Our completely non-destructive and non-contact component testing method reveals what other methods can’t, such as hidden defects, internal structures and complex geometries. It provides a 100% capture of the component’s actual condition.

Our CT systems are equipped to handle all your 3D measurement and analysis needs. We use three distinct X-ray technologies:

- Microfocus tube – the established standard in CT technology.

- High-flux technology – we use this for components that are more challenging to scan (e.g., denser materials). This method delivers superior data quality.

- Nanofocus tube – as the name suggests, the focal point of this tube lies within the nanometer range.

Applications

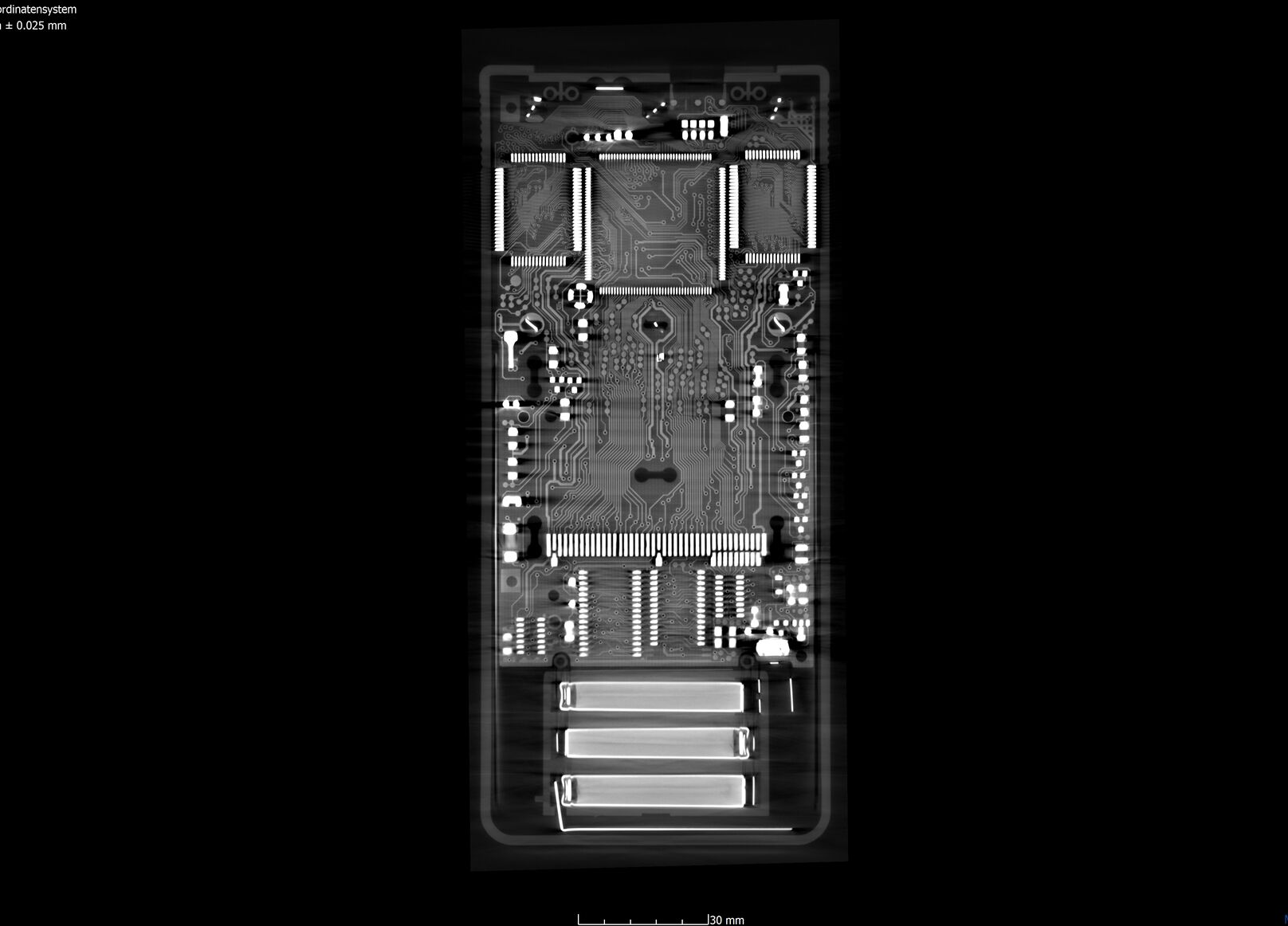

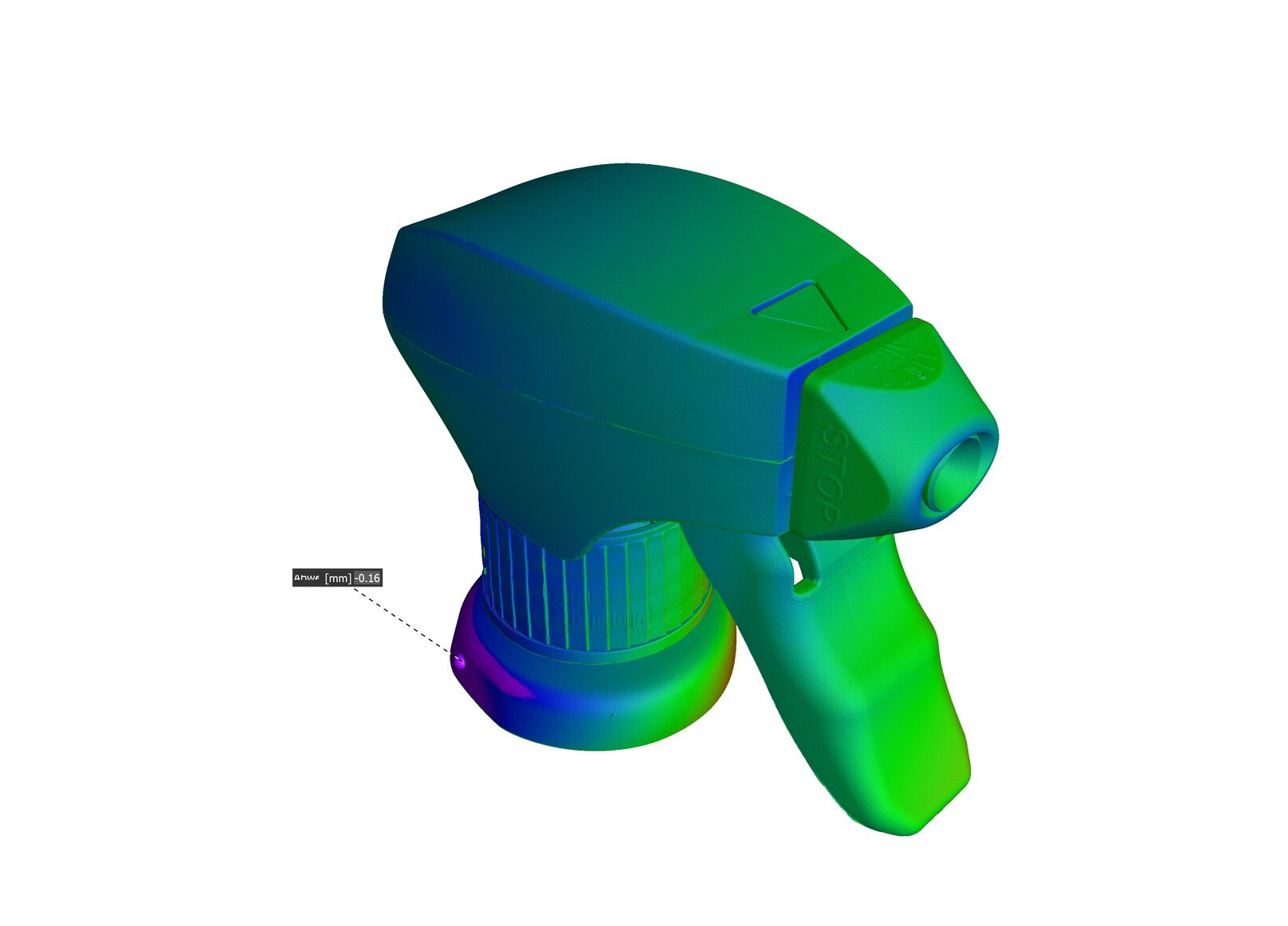

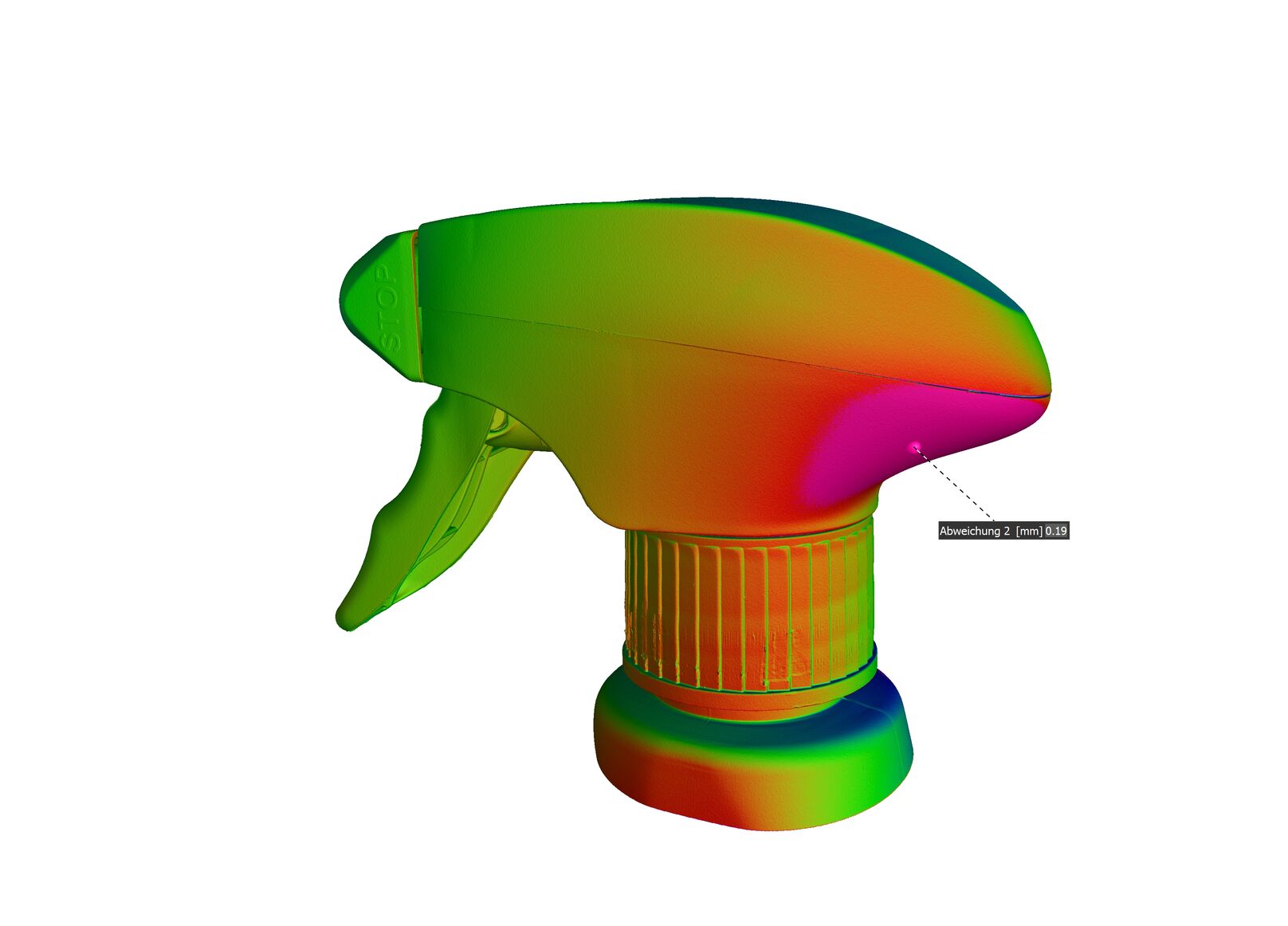

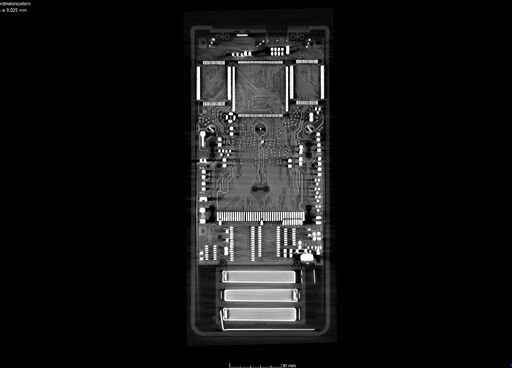

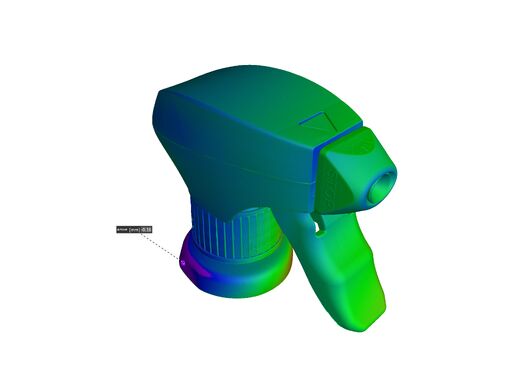

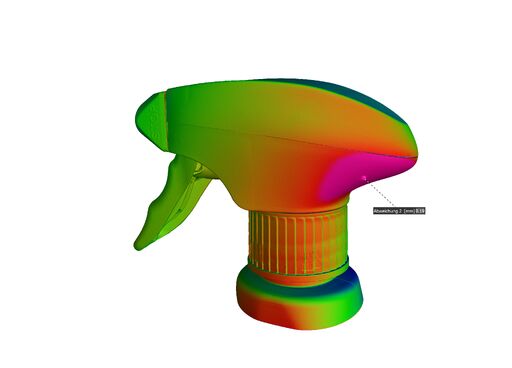

Computed tomography is currently the most detailed method available for fully digitizing components. It can create digital twins, provide data for quality verification, and serve as a basis for reverse engineering or additive manufacturing. The data it generates forms the basis for all subsequent analyses. Here are some examples of its applications: First Article Inspection (FAI, including according to ISO GPS standards), nominal-actual comparison, assembly analysis, defect analysis (porosity, voids, cracks, collisions), wall thickness analysis, fiber composite analysis, derivation of tool correction data, creation of simple 2D X-ray images, for example, for checking printed circuit boards in the electronics industry.

We also prioritize quality and experience in our choice of analysis software. We use Volume Graphics VGSTUDIO MAX, ZEISS INSPECT, and ZEISS CALYPSO.