Optimizing PET bottle closures

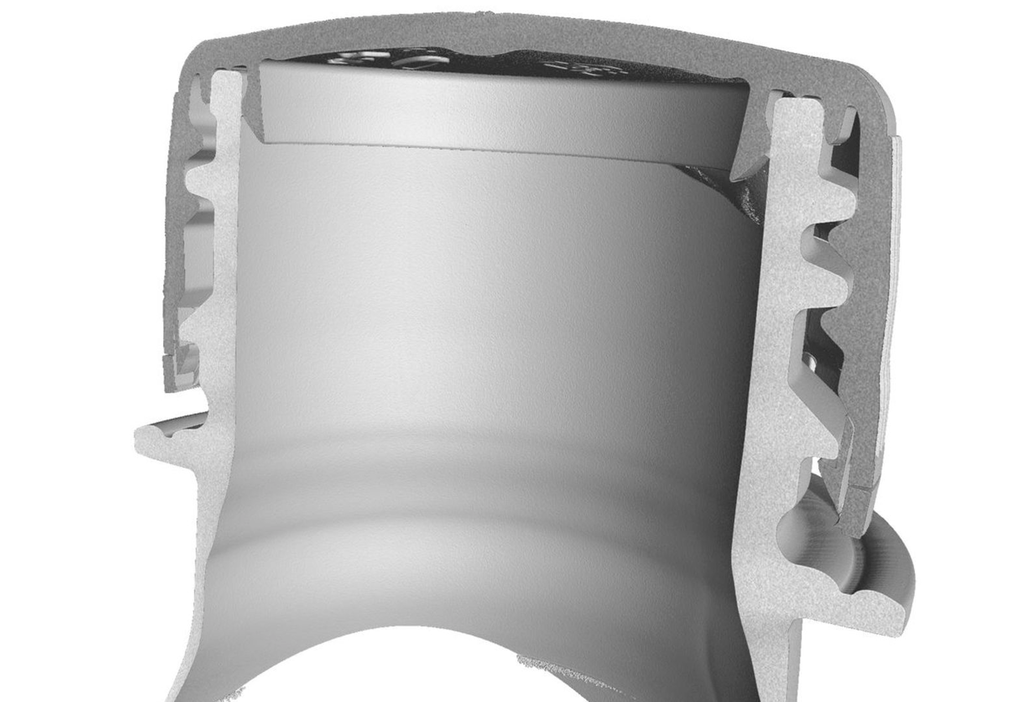

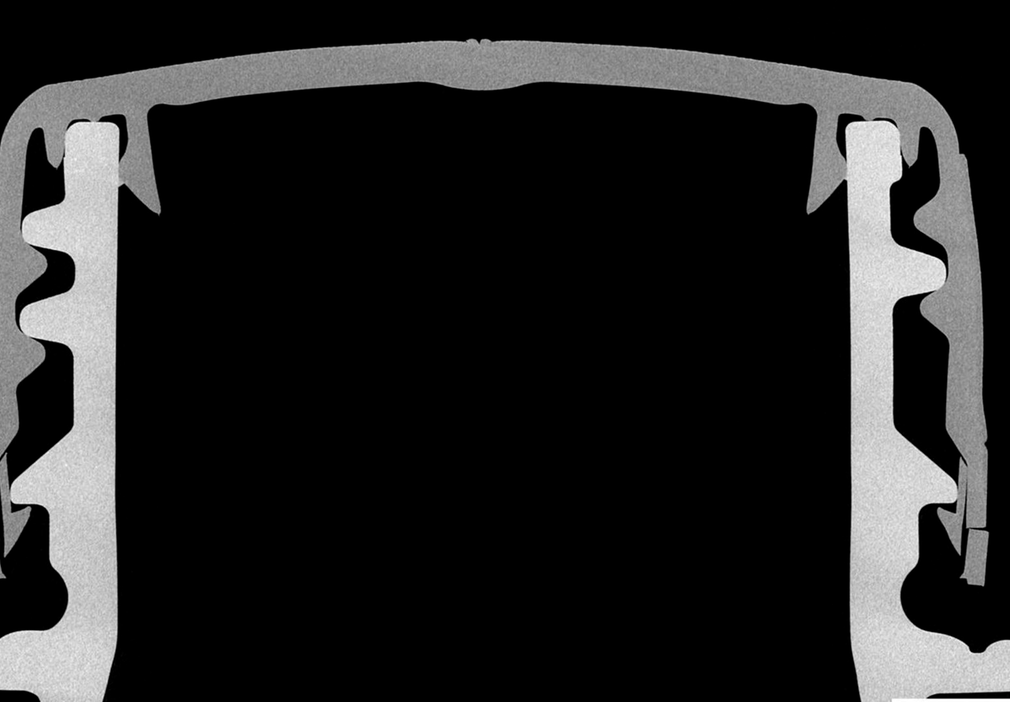

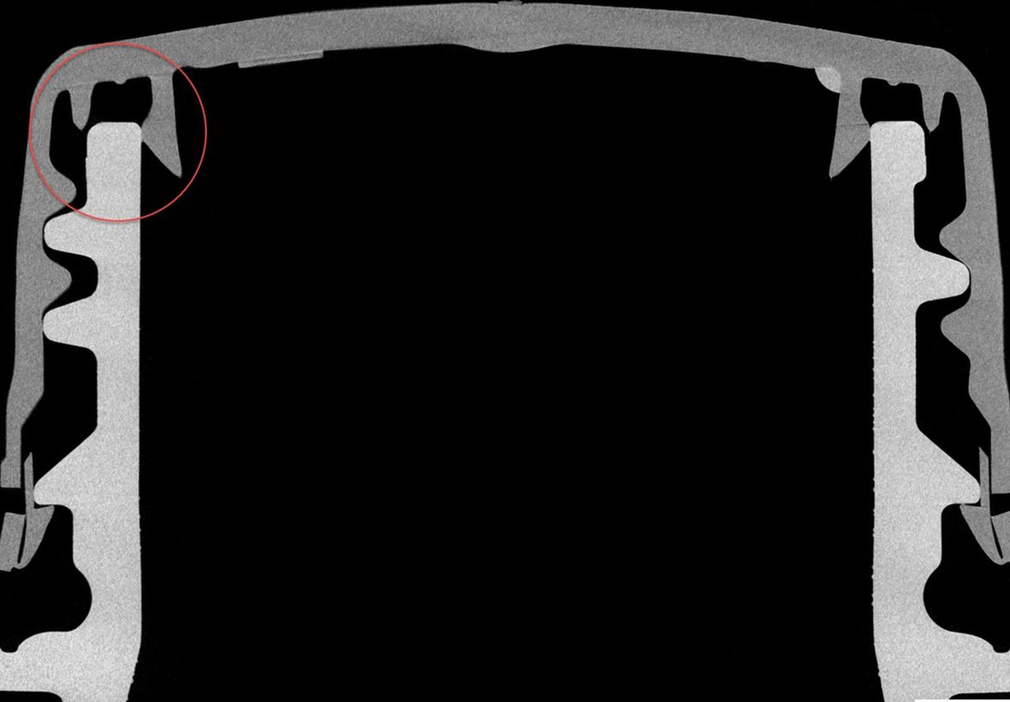

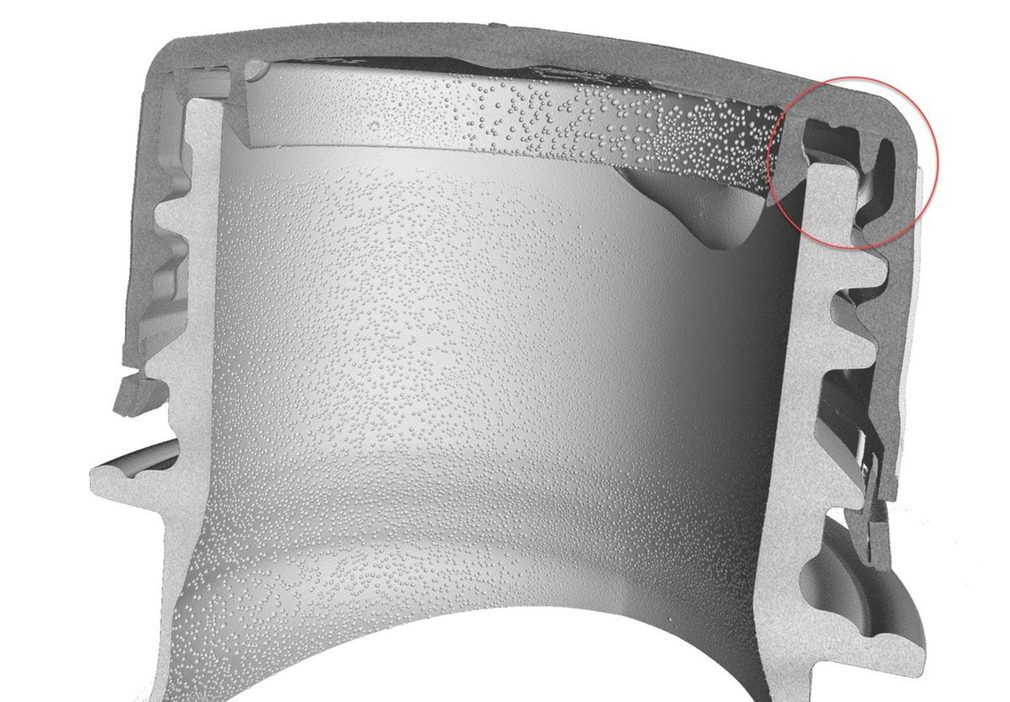

PET bottle closures are complex components that include a variety of seal geometries performing distinct functions. The tiny threads must fit precisely into the screw cap to ensure that the carbon dioxide escapes first, and only then is the bottle opened for the liquid. Our customer from the packaging industry approached us with a problem concerning their PET bottle closures. When the bottles were opened, the pressure was not releasing first (before the closure was fully opened) as intended. As a result, the cap would spring off under pressure upon opening, potentially causing the beverage to spill. Using CT data, we were able to demonstrate the tightness of the closures at various opening angles and under pressure. Our measurement data revealed that the cap was still maintaining a seal even though the thread was already relieved and the cap was still held on by the tamper-evident band. Based on the data we generated, the manufacturer was able to make targeted changes and resolve the issue.